Diamond techniques

The technique of diamond cutting and drilling in construction materials such as reinforced concrete, concrete, ceramics, etc. involves the use of special discs, wires or drills with high wear-resistant diamond elements.

Application of diamond techniques

Diamond techniques are used extensively in selective deconstruction of structures, where only a section is subject to removal while the remainder is intended for further use. We use the technique for modernization and renovation work, as well as on newly built structures. The wide range of applications allows a large range of work in construction materials.

Cutting openings in walls and floor slabs

This state-of-the-art technique is currently fastest method of making passages and penetrations in walls and floor slabs. Diamond technology is perfect for cutting openings for the installation of windows, doors, ventilation and air conditioning shafts..

Making furrows in concrete

The diamond cutting method has also found wide application in making all kinds of furrows.

Drilling in concrete and other construction materials

Diamond drilling in concrete is used to make all kinds of cylindrical openings, from small to very large diameters. This drilling method has found a very large application in the installation of electrical, sanitary, ventilation, air conditioning, heating, telecommunications, gas, etc.

We also use diamond drilling frequently in the installation of culverts, anchors (glued in, expansion, through), columns, railings or taking concrete samples for analysis.

Advantages of diamond technology

It is a non-impact and dust-free method. Cutting out sections using this technique guarantees that the remaining load-bearing structure will not be weakened, and the resulting cut surfaces will be smooth, clean, with even edges.

Advantages of using the diamond cutting and drilling method:

- low noise level and no vibration that would disturb the statics of the structure

- no dusting

- high precision providing an aesthetic surface finish

- wide selection of parameters providing a wide range of possibilities for work on different surfaces

- high efficiency of cutting and high quality of work result

The efficiency of diamond techniques has caused their rapid development, which is reflected in a wide range of types of equipment, the operation of which is based on the method of diamond cutting or drilling.

Today, virtually any construction material, including reinforced concrete, asphalt, construction ceramics, stone and glass, can be processed using diamond techniques.

Traditional concrete processing methods and their disadvantages

Conventional methods of drilling require a lot of labor, the progress of the work is slow, and it generates a lot of noise and dust, which excludes this type of technique at the finishing stage. When drilling holes in reinforced concrete, there is also the need to cut reinforcing steel, which further lengthens and complicates the work.

With all these inconveniences, the results of traditional work methods are far from being the best: the openings have imprecise dimensions, the edges are irregular as a result of concrete crumbling, the vibrations generated during the work cause micro-cracks in the concrete, which greatly reduces its strength.

An ideal alternative to traditional methods is diamond cutting and drilling.

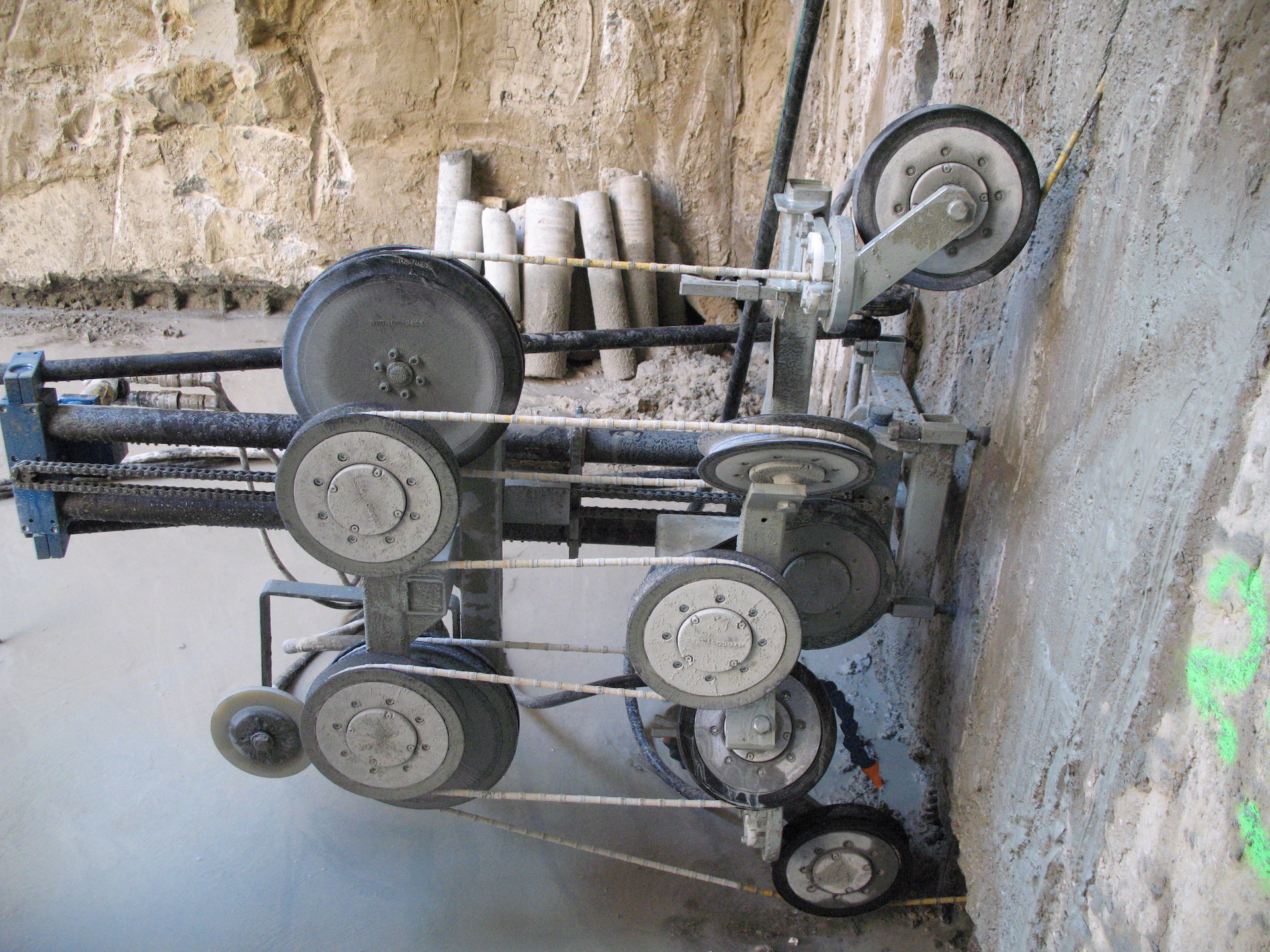

Equipment in diamond technology

The equipment used in deconstruction of buildings using non-impact diamond techniques includes: hand and tripod drills, wall and road circular saws, wire saws, hand cutters, etc. We carry out the work using top-of-the-line specialized equipment - including that by HILTI and TYROLIT HYDROSTRESS.